Having a solid understanding of Walmart pallet requirements is imperative if you ever want to be one of their vendors. With a yearly revenue that leaves even Amazon in the dust, Walmart is the biggest retailer in the world. If you want to do businesses to them, you’ll need to follow their strict pallet requirements when sending them freight in bulk.

Key takeaways:

These are a few requirements you’ll need to know, but we’ll go over many more in the rest of the article.

While Walmart has a variety of rules for their pallets, they also have guidelines for boxes and containers that you’ll have to satisfy. Fortunately, there are a variety of box types Walmart will allow you to use.

This includes:

Boxes and containers must weigh no more than 150 pounds. An exception can be made if a single unit within a box exceeds 50 pounds, but you will have to put “Team Lift” labels on the top and side of it. Any box that has a single unit greater than 100 pounds will need a label that says “Mech. Lift” on the top and sides as well.

Walmart also has guidelines for packaging items in individual boxes, even if they’re palletized. First, let’s go over the acceptable packing materials that you can use.

The packing materials you decide to use should offer reasonable protection and keep the item contained within the box. Even though your individual boxes will be secured to a pallet, you’ll need to provide a shipping label for each one.

Here is the information that should appear on the label:

The recommended size of your shipping label should be 4” x 6”, but they can be larger or smaller depending on the size of the box. Place the label left of center on the longest side of the package. If the label doesn't fit on the side, simply place it on the top of the box.

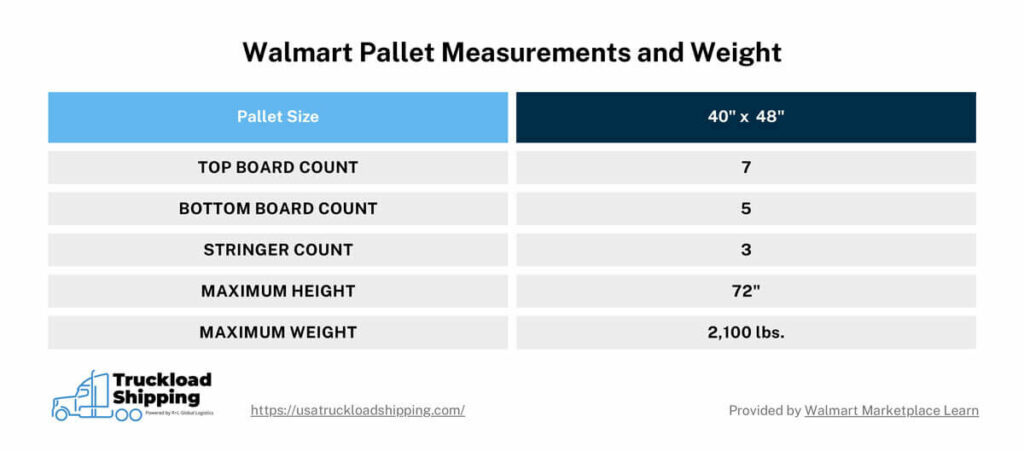

Walmart Marketplace has numerous dimensional and weight regulations for pallets sent to their warehouses and supermarkets. They also have rules for how many bottom boards, top boards, and stringers that should come with your platforms.

I’ve provided a graphic that clearly represents these requirements. The included in the graphic were provided by Walmart Marketplace Learn.

If you’re shipping an item that can’t fit on a 40” x 48” pallet without overhanging, you can use a larger platform that’s suitable for it. In the case of double stacked pallets, the load cannot exceed 108” in height.

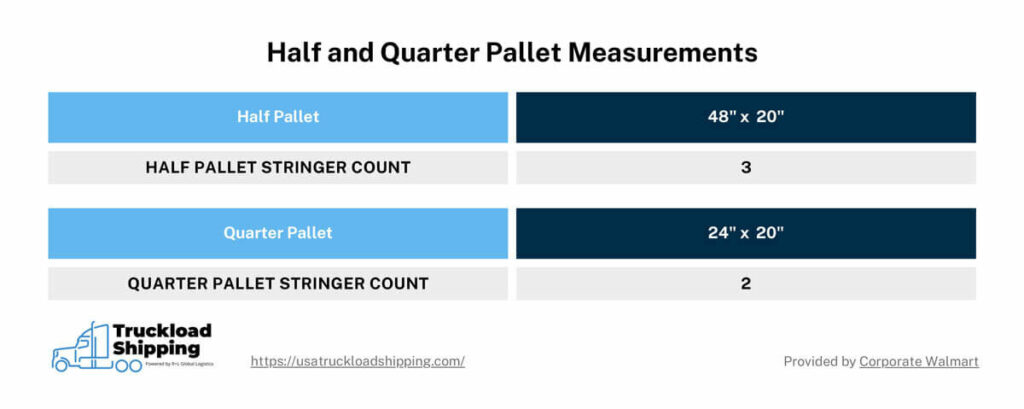

For certain approved programs, Walmart will permit you to send half and quarter pallets. Here is another graphic that shows the acceptable measurements for these platforms provided by Corporate Walmart.

All pallets, regardless of size, should be able to accommodate standard pallet jack and forklift equipment.

Walmart accepts Grocery Manufacturers Association (GMA) Standard Grade A Pallets. GMA isn’t a brand, but a standard that pallet manufacturing companies can use for production. These platforms come in the accepted 40” x 48” size. They typically meet the seven top board and five bottom board requirements as well.

Walmart wants all suppliers to use pallets that are in good condition. To ensure you send pallets that are acceptable, you’ll have to satisfy a strict set of standards.

Pallets with the following features are not allowed by Walmart:

Make sure that your pallets have stringers that are solid and unbroken. They shouldn’t have visible cracks on three sides that are more than an inch long. Weathering cracks are allowed, as long as they’re not continuous and not visible from three sides of the platform.

All pallets sent to Walmart must abide by ISPM-15. This is an international standard that requires wood packaging materials to be heat treated or fumigated. The purpose of ISPM-15 is to eliminate pests and diseases inside the wood packaging materials that could have an adverse impact on the environment.

Fortunately, you won’t have to go through the trouble of heat treating or fumigating pallets yourself. Most pallet manufacturers ensure their pallets meet ISPM-15 requirements prior to sale. You’ll just need to make sure the company you purchase your platforms from are in compliance with this rule.

If using wooden pallets isn’t your preference, Walmart allows you to use pallets made from other materials, such as plastic and metal. However, you will need to have approval from Walmart Inbound Transportation to use these platforms.

You may also need to provide proof of the structural capability and/or fire rating for your pallet. Despite allowing suppliers to use different materials for their platforms, Walmart will not accept corrugated pallets under any circumstance.

Now that you know the requirements and standards for Walmart pallets, it’s time we discuss their rules for loading freight onto these platforms. These guidelines will ensure your cargo is acceptable and safe upon delivery

There are two primary methods that Walmart allows packages to be stacked on pallets.

While these are the two primary methods for loading freight on a pallet, hybrid stacking is another option. This option combines the column and interlocking methods together.

Walmart allows shippers to place slip sheets in between boxed freight loaded on pallets. However, you’ll need to meet a few requirements first.

A slip sheet is allowed to be larger than 48” x 40”, but only for oversized items. If the freight on your pallet requires more stability, Walmart will let you use tier sheets. These come with their own set of requirements you’ll have to satisfy.

This includes:

If you still need additional stability for your shipment, but don’t want to use a tier sheet, a Walmart Inbound Quality Senior Manager can give you approval to use alternate materials.

Palletizing bagged products is a little more difficult than standard boxes. However, Walmart has some requirements that will make this task easier.

Here are the steps they recommend you follow

Pre-assembled and corrugated PDQ displays are another tricky item to palletize. Here are the steps Walmart will want you to follow when you send this kind of freight to their distribution centers.

You must a 48” x 40” platform, or another platform that will hold it securely.

Now that you know the acceptable ways to load your freight, it’s time to learn how to keep it secure using stretch wrap. Walmart requires that you should use a minimum of 80 gauge, 15” stretch wrap.

When you start wrapping a pallet, begin at the bottom and work your way up. Make sure that you wrap in an overlapping pattern every 2 to 4 inches as you go. Also, make sure that when you start applying the stretch wrap, you don’t block forklift entry holes with it.

Walmart does prohibit certain types of stretch wrap, so check your packing center to make sure they don’t use the following:

When stretch wrapping your palletized shipment, you will need to pay close attention to the containment force you use to secure your freight. The amount of containment force you use can vary based on the type of freight.

This force is measured in pounds. It must be applied consistently during the entirety of the palletized freight’s journey. The containment force should also be appropriate to the freight itself.

Once your freight is stacked and wrapped, you will then need to put pallet labels on. Walmart requires all palletized shipments to have a pallet label. Walmart does not provide a template you can use, but they do provide guidelines for what should be included on each label.

The following information must be present:

These bits of information are required under every circumstance. However, you can include some optional information, such as:

If you send a pre-assembled display or a pallet pull to Walmart, you will need to include the 14-digit GTIN on the pallet label as well. If your palletized shipment is made up of only one type of item, then you will need to include the item number below the purchase order (PO) number on the label. The placement of the label on the pallet should be on at least two adjacent sides.

The label can be anywhere on the pallet’s sides, but Walmart prefers them to be in the top right-hand corner of the pallet. Lastly, an ITF-14 barcode will be needed in addition to the SSCC-18 barcode already required.

Pallet placards are not always needed, but when they are, they’re not a replacement for a regular label. The required size for Walmart placards is 8.5 by 11 inches.

Placards will be required for the following types of pallet shipments:

Placards might be needed for pallet shipments to:

In addition to their size requirements, the lettering on the placard must be large and easy to read. The placement of the placard should also be in the upper middle of the palletized shipment.

Related: How To Reduce Transit Damage

Now that your palletized shipment is ready to be transported, you will need to have the proper documents ready for domestic shipping. The only document that you’re required to have is the BoL. However, you can include a packing list as well.

If you choose to include a packing list with your palletized shipment, you need to make sure that the information that you provide in it matches what you’re sending. It needs to be in a clear plastic envelope attached to the outside of the last carton of the shipment.

The envelope should be on the side of the pallet facing toward the door of the trailer so it’s visible right away. If you’re sending multiple pallets, you will need a copy of the packing list for each one, while using the same guidelines.

Include the following information in your packing list:

Ensuring you have all the relevant information included on your packing list allows Walmart staff to receive and unpack your pallet more efficiently.

While packing lists are optional, BoLs are necessary for palletized shipments to Walmart. When you include a BoL, you’ll place it in the same clear envelope as the packing list.

Your BoL should have the following information about your palletized shipment:

As a seller/supplier to Walmart, the information included in the BoL must be accurate to the palletized shipment itself.

Related: 8 Types of BoLs

You’ll need to abide by Walmart’s supplier responsibilities when sending them palletized freight. Rather than getting into all the specific details, we’ve listed the guidelines you’ll be expected to follow.

You can learn more about your responsibilities as a supplier from Walmart’s various resources.

At USA Truckload, we have a large network of small carriers all over the country that can transport your pallets to a Walmart warehouse or supermarket. With the help of leadership that has 30 years of experience in the logistics industry, we’ll find the perfect carrier to pick up your cargo.

We can provide you with a variety of transportation services, such as:

Get started with our services by filling out your Request for Proposal (RFP). You can also contact our team (866) 353-7178 if you have any questions.

R+L Global Logistics

315 NE 14th St., Ocala, FL 34470