To minimize transit damage and reduce freight claims, implement the following practices:

Implementing these strategies can significantly enhance the safety and integrity of your shipments, leading to fewer freight claims and improved customer satisfaction.

Freight damage during shipping isn’t avoidable all the time. Accidents on the road and in the warehouse can and will occur. However, being proactive about shipment safety goes a long way toward reducing freight claims and keeping your clients happy.

We'll review nine ways that you can impact your shipping practices for the better to reduce freight claims and keep your customers coming back.

In any industry, accidents that damage merchandise and potentially put people in danger can and will happen. In the shipping industry, with transports ranging in size from super yachts that get moved by flatbed across the country to specially ordered ugly Christmas sweaters, drivers and warehouse workers need to prepare for all of it.

Shippers who practice safe methods of packaging help reduce damage in transit and in warehouses. The more shipments arrive safely to their final destination, the fewer freight claims for damage and loss will need to be filed.

Let’s look at nine ways you can reduce transit damage while also reducing freight claims.

Choosing the correct packaging is the first step to reducing freight claims. Both size and material play a part in keeping items safe.

When selecting the boxes, don’t go for the one-size-fits-all approach. In a box too big, items may shift more than necessary and break. Too small, and your items won’t fit at all. The perfect size is one that fits your items with just the right amount of packing material.

You should also look at the material the boxes are made from. Some are meant to be stacked and some aren’t. Get these confused, and you risk thousands of dollars in damage, even when boxes are stacked neatly on properly sized creates.

If you are committed to sustainable shipping solutions and are planning on reusing boxes, these should be carefully checked for damage. Even minor damage can affect a box’s structural integrity and make your shipment more prone to issues like water damage.

Once you’ve determined the right size and material, make sure you are not exceeding the manufacturer’s weight limits. Just because you can fit 300 pounds in a box, doesn’t mean you should.

Heavier items that can’t be divided may be better off in a wooden crate, something sturdier than a box and able to handle the weight. If items can be split up, consider a smaller box for heavier and denser items.

Not all tape is created equal and even when using good quality tape, you need to choose the right one for the job.

For however perfectly you chose boxes, if they aren’t sealed correctly, it's not going to matter. When picking a tape, consider where and when your boxes are being moved. You should also consider the nature of what you are packaging.

Some good tape options are listed below.

No matter what you choose, paying a little extra for better quality is worth it. Packing tape is a small part of your overall shipping budget, but that doesn’t make it any less important.

Proper palletizing starts with quality pallets. Made out of wood or plastic, freight shipping would be almost impossible without them. There are a few different standard sizes available when it comes to purchasing mass-produced pallets.

The three most common sizes are:

The first, commonly referred to as a 48 x 40 GMA (Grocery Manufacturers Association), is the closest thing to a standard pallet that exists in the United States. Most are designed to be easily used with a pallet jack, a tool essential in every warehouse for moving heavy loads.

Whenever possible, boxes should be stacked on pallets in such a way that there is no part of them hanging off or empty spaces in between. This makes the use of other protective tools like corner protectors, shrink wrap, and banding easier to apply.

Wood pallets are versatile and able to hold over 4,000 pounds in most cases. Damaged or poorly constructed pallets may break during transport, so if you reuse pallets, be sure to inspect them during each shipment and take out damaged ones.

Plastic pallets are also available, but aren’t as easy to alter if needed. Wood pallets can be adjusted to custom-sized loads with relative ease. Plastic pallets also can’t handle the weight wooden ones do and are more expensive.

However, if you are shipping food or anything requiring strict cleaning requirements, plastic is the way to go since they are easy to wash and sterilize.

If you want your packages to be extra secure, wooden shipping crates can also be used. Items that are especially bulky or of awkward dimensions that won’t box well can be shipped in large crates. Customs crates can also be ordered.

As an added benefit, crates are easily doubled stacked. Pallets can be as well, but only when materials have been properly boxed. As with pallets, be sure you are using well-constructed crates, and if reusing, check for damages with every shipment.

Related: Walmart Pallet Requirements

Having taken care of the outside materials, now you should examine the packing material going into boxes. No matter how smooth, vibration from the road or even the truck's engine can cause items to shift and lead to damaged goods.

Good packing materials provide adequate protection while not adding significant weight to a shipment.

After your items are placed in boxes, empty space gets additional packing material. These work to prevent items from shifting too much during transit and provide impact protection if mishandled or dropped.

Common packing materials include:

For additional protection, you can also use banding groove lumber that holds polymer or metal bands in place while preventing damage to boxes themselves. While not a packing material, it provides even weight distribution, especially during stacking.

Boxes on a pallet should be held together with bands and shrink wrap whenever possible. Done properly, wrapping should cover the pallet, too.

Using a dark or black wrap also serves to prevent theft because the contents of each shipment are hidden from the casual observer.

Reducing product damages not only reduces freight claims, but final mile delivery problems as well. According to recent consumer surveys, damaged items were among the top three reasons for returns in ecommerce, accounting for 65% of people asked.

Your packing material needs will depend on your items. A combination of the materials above should provide you with a wide range of options best suited to your needs.

Related: Shipping Skid vs Pallet

Shippers can control many aspects of the shipping process, though ultimately the carrier is the one responsible for loading and unloading the trailers.

Even so, shippers contribute to efficient trailer loading by having their packages well palletized and labeled. These allow carriers to more effectively fill trailers and avoid significant gaps between packages that make things more likely to shift in transit.

If you’re responsible for prepping loads, follow these basic guidelines:

Carriers should provide you with their freight loading procedures and practices. Most have detailed freight loading plans to maximize efficiency. If your freight company isn’t able to, it could be time to look for a different carrier.

There may be no such thing as too much labeling. Labeling isn’t just so carriers know where something is going. Freight labels protect your shipment by indicating how packages should be moved and stored.

A freight label includes the:

Some labels are required by law, such as Hazmat labels, which are regulated by the Federal Motor Carrier Safety Administration (FMCSA).

Labels indicating how a package should be handled can prevent mistakes that would otherwise damage an item. These include warnings such as:

These and others should be placed on multiple parts of a package where they can easily be seen by handlers. It goes without saying they should be double-checked before placement; especially directional labels.

If the freight label has a barcode for easy tracking, which most do, make sure it is accessible and visible for anyone scanning shipments. Freight getting divided up at a cross docking station needs to have labels on individual boxes to guide workers during pallet breakdowns.

Freight claims are most common for shipments involving fragile items. Liquids are another common source. Liquids being transported in fragile containers, such as perfumes or liquors, combine the worst of both.

If you are shipping a variety of items, ranging from the very sturdy to the very delicate, you’ll want to keep them separate. The additional money spent on more boxes and packing material will be worth it when your items arrive intact.

A freight claim may get you money back on broken items, but it does nothing to help the clients who will still be waiting on their orders.

Consider these guidelines when preparing a load:

While it might sound nice, shipping everything in wooden crates would be too expensive. Following the guidelines I’ve outlined should cover most liquid-based transport needs.

Related: Blanket Wrap Shipping

Another thought to consider when trying to reduce freight claims is your chosen delivery method. Not necessarily the carrier, but the service.

Many companies are taking advantage of Less-Than-Truckload (LTL) shipment services. These can get your goods moving out faster and typically at a good price, but have a history of frequent freight claims.

Full truckload services reduce freight claims because they reduce a shipment’s total touchpoints. LTL carriers may load and unload parts of shipments several times a day or per shipment. These frequent touchpoints increase the chances of something getting damaged.

Just because something was stacked perfectly during the initial load, doesn’t mean it's going to stay that way the whole ride.

Although better technology and processing have reduced LTL freight claims, it's still a risk you may not want to take. FTL services can take your freight from point to point with little to no handling. Fewer touchpoints mean fewer chances of damage.

The shipping costs are likely to be more expensive, but it may be worth it. A secondary option is partial truckload shipping (PTL). It works a little like LTL, but without all the different stops. PTL offers direct shipping of partial loads heading to the same area.

It minimizes damage, but filling a trailer can take longer since it all has to be destined for the same place.

Partnering with a Third Party Logistics (3PL) company to manage fulfillment and distribution can resolve many of the issues we’ve discussed. 3PLs with warehousing capabilities will have the right tools and equipment to correctly box and palletize shipments.

A 3PL gives you access to the technology they use to track warehouse inventory and shipments out for delivery. This way, whether you use LTL or FTL services, you know where your shipment is supposed to be at any given time, reducing freight claims due to lost shipments.

With a 3PL, you also aren’t locked into one particular carrier. Logistics companies may work with multiple carriers, and because of their experience in the field, they know which ones are the most reliable. Involvement in multiple levels of the process also protects more of your supply chain.

At USA Truckload Shipping, in addition to truckload services, we also offer warehousing, fulfillment, and other logistics services. Get in touch and find out how we can partner with you to handle your freight throughout the entire supply chain.

Lost and damaged freight translates to monetary loss for shippers. The freight claim process exists as a way for shippers to recover lost funds. However, even if a freight claim can get you back 100% of the money lost, time is another matter.

Let’s review a simplistic version of a single shipment to determine possible losses.

Item A is being shipped from your warehouse to a distribution center by an LTL carrier. You are shipping 500 units of Item A that cost you $5,000. Also consider the expenses related to actually shipping those units.

If the shipper can sell all 500 units of Item A for $20.00 each, they will earn $10,000. Their profit after the listed expenses is $4,200. With it, they can purchase new merchandise to repeat the process all over again.

However, if half the shipment is damaged, that number changes significantly.

Let’s say that along the way, half the freight is damaged when an improperly stacked pallet (not yours) is tipped over onto your items while being unloaded at one of the stops. The value of what you lost is $2,500 not including potential profit from sales. Here’s how that breaks down.

With only half the items available to sell, potential profit drops to $5,000 leaving a deficit of $800 for this particular shipment.

Even assuming that a properly filed freight claim recovers the $2,500 value of lost merchandise, you’ve still lost the potential profit. Also, consider that the average freight claim can take three months to resolve.

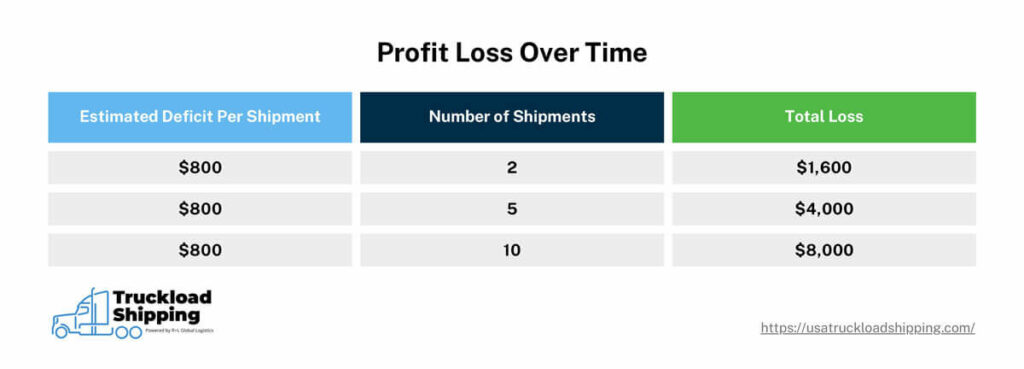

If this type of loss is happening routinely across identical shipments, you are losing thousands of dollars.

Depending on how often you ship per month, you could be losing as much as $8,000 that you hope will be paid back to you with a freight claim sometime in the next three months.

Even with such a simplistic example, as someone running a business, it’s safe to assume you wouldn’t think this is a sound business model.

The current shipping industry, both in the U.S. and worldwide, has been heavily affected by delays, labor shortages, and production disruptions. These have become chronic issues that must be managed daily rather than as occasional problems.

Damaged and lost freight can no longer be physically replaced as easily as it once was. You may have the money from a claim, but that is all. You still won’t have a product to sell. It may be months before you can get more of a product, depending on what it is.

Getting your freight to its destination in one piece is more valuable than reclaiming lost value.

Stop wondering how to reduce transit damage on your own. Move your freight with USA Truckload Shipping and work with professionals who value your shipments. Our massive network of carriers allows us to provide you with various perks.

We can get you trucks with liftgate capabilities and weather shields to keep your freight safe and make unloading and loading services painless and hassle-free. Your freight is important to you and your business, and that makes it important to us too.

USA Truckload Shipping can offer services for:

Trust your shipments to the experts at USA Truckload Shipping and fill out your Request for Proposal (RFP). You can also call us today at (866) 353-7178 or fill out a contact form if you have any questions about the services we provide.

R+L Global Logistics

315 NE 14th St., Ocala, FL 34470