Navigating peak shipping season can feel like riding a rollercoaster for businesses hustling to get products to stores and customers. With order volumes soaring, and delivery networks stretched thin, challenges like shipping delays and inventory management issues can become overwhelming. Fortunately, there are methods you can use to overcome these challenges.

Key takeaways:

Now that we have the basics out of the way, let’s dive into the challenges of peak shipping season and the solutions you can use.

Peak shipping season refers to specific times of the year when there's a significant increase in the volume of goods being shipped. This surge is primarily driven by heightened consumer activity around major holidays and shopping events.

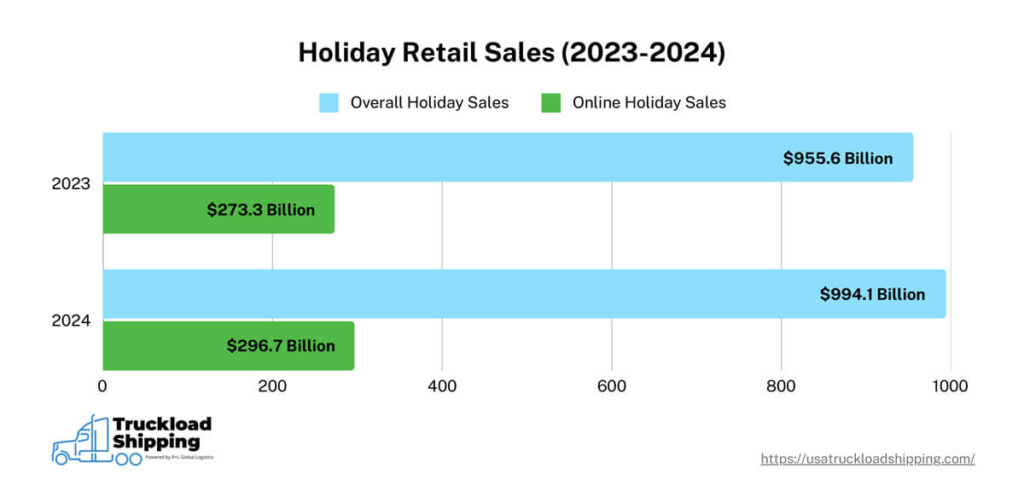

To show how often consumers are buying during the holiday season, consider some data we’ve included from the National Retail Federation (NRF).

For retailers and ecommerce businesses, peak shipping season is a critical time when efficient logistics and supply chain management are essential. Without proper preparation, you won’t be able to meet customer expectations and capitalize on increased sales opportunities.

Related: Shipping Clothes and Shoes

While peak season starts and ends at different times for various industries, it typically kicks off in August and ends in January. Here’s a list that shows some notable holidays and events that drive consumer demand.

You’ll need to adjust your peak season preparations in accordance to the holiday that most impacts your business. Keep in mind that while those are the peak times for shoppers to be buying, businesses need to have their merchandise in place well before. Shipping logistics need to be handled at least two to three months in advance for most industries.

Peak shipping season is one of the busiest and most demanding times for retailers, no matter what their business platform is. As order volumes surge, so do the logistical hurdles that come with moving freight efficiently.

Challenges you’re likely to encounter include:

Before you can learn how to overcome these challenges, you’ll need to understand why and how they occur.

During peak season, various logistical services will increase dramatically. This is due to the strain that increased demand will put on transportation and warehouse services.

Expenses that you can expect include:

All these expenses can add up and put a real strain on your business. Developing a strategy that pays for these costs without breaking the bank is essential.

Related: 10 Ways To Reduce Freight Costs

It’s important to note there is already a labor shortage in the logistics industry, particularly in regard to the amount of truck drivers. The American Trucking Association (ATA) predicts there could be a shortage of 160,000 drivers by 2028. This shortage will be felt most during peak season.

The surge in order volumes during peak shipping season can be hard for your current workforce to handle. Labor shortages can lead to a variety of problems for your business.

This includes:

Without enough workers, your ability to fulfill orders quickly will begin to suffer. This is especially felt in the case of time-sensitive deliveries (no one wants to explain to their child why their present isn’t there by Christmas day).

Similarly, workers that are rushing to keep up with high order volumes are more likely to make mistakes. Businesses that add more shifts or require workers to come in on their days off during peak season can make this worse.

Employees that are working more hours without enough rest can suffer from burnout. When their performance suffers, so will the performance of your operations.

The trickle-down effects of a labor shortage directly impact consumers, and a poor rating of your services due to the mistakes I’ve mentioned can cause reputational harm to your business.

Carrier capacity can become strained during peak season due to an increase in demand for transportation services. Limited availability of carriers and shipping containers may result in delays and increased costs.

This can be especially problematic during the short timeframe between Thanksgiving and Christmas. Without the capacity you need to ship orders in a timely manner, your customers may receive the gifts they ordered for family in friends after Christmas passes.

While there are many issues that can arise during peak shipping season, there are plenty of steps you can take to ensure your business runs smoothly. Let’s take a closer look at what you need to do.

You should start preparing for peak shipping season at least a few months in advance.

This can be done by:

By studying historical sales and market trends, you’ll be able to figure out which products will be in demand when peak shipping season arrives. You can use this information to order the correct amount of inventory you’ll need.

As we’ve already discussed, warehouse staff can have trouble processing freight during peak shipping season. You can overcome this challenge by hiring seasonal workers to help pick up the slack.

To lower your transportation costs, try to secure favorable shipping rates from your carrier. This ensures your shipping expenses stay the same during peak season. Forming a relationship with a carrier also guarantees you’ll have access to transportation services, even as demand for shipping increases.

You should give your customers a heads-up that peak season is coming up. Tell them about expected delays, shipping deadlines, and any changes in operations due to peak season.

This is especially important for ecommerce businesses that may be practicing direct-to-consumer fulfillment from suppliers that are overseas.

You can get the message out using the following methods:

When you do start shipping orders, provide customers with real-time information regarding the progress of your shipment. Be honest about any increased shipping times. If you don’t already have a system like this in place, peak season is the perfect time to implement it.

Since high costs come with peak season, you’ll need to start budgeting ahead of time. There are few strategies you can use to lower your shipping expenses.

Regularly review carrier announcements regarding peak season surcharges and adjust your budget accordingly. If necessary, reflect increased shipping costs in product pricing or shipping fees to maintain your sale margins.

To avoid spot rates, which are often higher, enter into a contract agreement. This will make your costs more stable and help in budgeting.

Unless you already have an established a beneficial relationship with your supplier, it may be helpful to diversify your shipping options. There are two ways you can do this.

Using multiple carriers can mitigate the risk of capacity shortages and allow you to choose from different rates. Multiple modes of transportation may also lead to lower expenses. For example, consolidating smaller loads into a larger one can save you on shipping costs. These carriers may be able to offer seasonal contracts depending on the number of shipments and transport mode.

Related: How To Negotiate Freight Rates

Using the correct domestic shipping documentation and filling them out properly is essential during peak shipping season. Making even a small mistake on your paperwork can lead to incorrect shipments, regulatory violations, and mistakes in inventory management - the last thing you need in a time crunch situation.

Practices you can implement to keep your paperwork correct and organized includes:

Training your workers in all these practices will ensure your domestic shipping documents will always be correct.

Any inefficiencies in your warehouse operations can be detrimental during peak shipping season. Optimizing these tasks can lead to faster order processing and reduced errors.

Implement strategies such as:

By enhancing your warehouse and fulfillment operations, you can better manage the increased demands of peak season and maintain high service levels.

Partnering with a third-party logistics (3PL) provider can offer scalability and expertise during peak season. They can provide a variety of resources that enhance your logistics operations.

These include:

At USA Truckload Shipping, we can provide all the benefits we’ve listed and more with our network of truckload carriers and warehouses.

If you’re looking for a reliable 3PL during peak season, then USA Truckload Shipping can help. Our extensive network of carriers is ready to pick up and deliver your freight. With our 99.5% on-time delivery rate, you can count on your shipment arriving promptly at the final destination.

We also have an assortment of other services you can enjoy:

Don’t wait until it’s too late—secure your shipping strategy now. Fill out a Request for Proposal (RFP) to start your relationship with USA Truckload Shipping. Call us at (866) 353-7178 or go to our contact page if you have other questions.

R+L Global Logistics

315 NE 14th St., Ocala, FL 34470