Businesses moving large shipments, whether once or on a regular schedule, tend to benefit from full truckload pricing. Since managing your shipping expenses is not a one-size-fits-all solution, it’s best to understand how brokers and carriers calculate their rates for this service.

Key Takeaways:

Find out which factors affect FTL shipping costs and how to calculate estimates based on freight needs.

Full truckload shipping (FTL) is generally used when a company needs to move items that are going to take up the majority of a standard dry van trailer.

This can mean goods with a combined weight of around 40,000 pounds or just over 20 loaded, standard sized pallets (typically 48”x40”).

Alternatively, FTL shipping is sometimes used for sensitive freight, either fragile goods or time-sensitive shipments that need to reach their destination with minimal stopping points.

If you’re looking to move smaller shipments (fewer than 10 pallets), less-than-truckload (LTL) shipping would be preferable.

Once you’ve determined that you need to move your shipment via full truckload, it’s time to start getting price estimates. How do you know what’s fair or not? Let’s break it down.

The base calculation that carriers use to determine FTL works on either a price-per-mile system or a flat rate. In both cases, businesses should expect to see a difference based on the trailering mode. The main ones are:

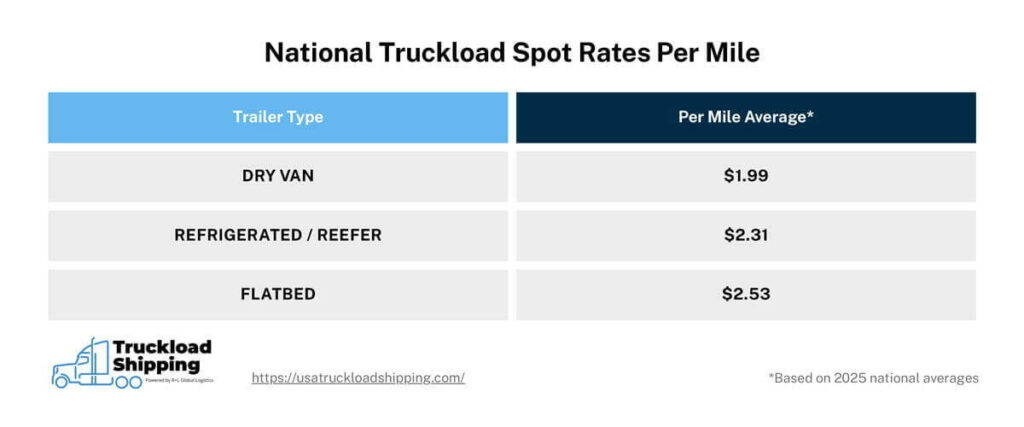

Different trailers vary in terms of cost and rates by region, demand, and capacity. Before calculating estimates, it’s a good idea to check averages for your area. For a quick snapshot, I’ll provide the national spot rate averages for the three just mentioned.

Typically, higher capacity (meaning carriers have more open availability) will drive prices down. Higher demand will reduce capacity and drive prices up. Spot rates are also likely to be higher compared to contract rates obtained through a Request for Proposal (RFP).

When a carrier provides you with a per-mile rate, multiply the miles of the route by the rate you’re given to get the base price for the entire trip.

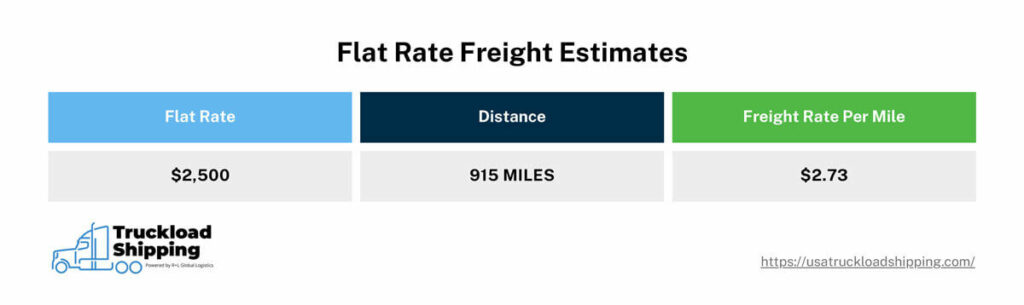

If a carrier provides you with a flat rate, and you want to make sure that it’s within the national average for your area, you just need to work the math a little backwards. Divide the total rate by the route mileage to get the per/mile freight rate.

Let’s assume that you routinely ship imported fruits from Miami, Florida to Nashville, Tennessee by reefer trailer- a distance of about 915 miles. A carrier quotes you a $2,500 flat rate.

In this scenario, the carrier is charging you about $2.73 a mile for the trip. While a little higher than the current average for reefers, you have to consider what else the carrier may be including in the price aside from distance, like the quality of their services or current fuel prices.

When it comes to reefer freight, as an example, you want the more experienced drivers and carriers because of the perishable nature of the goods.

The per-mile rate should still be within reason of the national average for the mode needed. If it isn’t, there are a few other factors that may be at play. Let’s look at those next.

These factors influence the final total. Some you can control and some you can’t. Other factors, beyond the control of even the carriers, are things like supply and demand or fuel prices, which further affects pricing. For now, let’s focus on more tangible concerns.

The farther your freight has to travel, the more it will cost. Since you’re charged a per mile rate for most FTL shipments, this seems obvious.

However, brokers and carriers tend to break down hauls by average length.

The mileage point where companies split each will vary, and some will have additional designations. Typically, a short haul will take a day or less, traversing no more than 250 miles. You’re likely to get a price per mile rate, or even just a flat rate, for a short haul.

Companies may actually provide you with a better per mile rate at long distances because they know the driver is being compensated for multiple days.

You still spend more for the longer haul, but the breakdown in price is slightly different.

To ensure proper shipping and handling, categorizing freight is necessary. Pallets of bricks, pallets of tomatoes, and crates of gas canisters have different needs to account for.

Whenever there is an increased risk of damage to cargo or the surrounding environment, should items be easily damaged or potentially hazardous, costs go up.

Getting good rates is easier when trucks are moving in and out of areas where loads are easy to secure. This is known as backload availability, and it makes it easier for the carrier and the driver to make money.

An empty trailer won’t bring in money, but will still cost the driver in time and gas. In trucking parlance, they’re called deadhead miles. Should your shipment need to go to a destination with poor backload availability, the rate is likely to increase to make up the costs of hauling an empty trailer to the next available load.

These are charges that carriers will add on for unique services or because of unforeseen circumstances. These can include:

Be aware that insurance that protects your financial investment in the cargo is different from the insurance carried by the freight broker or carrier to protect themselves from liability.

A carrier’s liability insurance is meant to protect the driver and company, not to provide a full payout to the shipper should there be damages during the shipment. A broker that includes separate cargo insurance for clients is often trying to help you protect yourself financially, knowing that the liability coverage won’t.

Related: Truckload Accessorial Charges Defined and Explained.

To better manage your freight shipping budget, there are a number of strategies you can adopt. Before we go on, I’ll point out that always going with the cheapest bidder is not among those.

Here’s what does work:

These and other strategies can help you better manage your freight budget and help you save money in the long term.

Related: 15 Easy Ways to Reduce Freight Costs

Don’t be confused about how to calculate FTL shipping costs; let the experts at USA Truckload Shipping help. Our services are backed by decades worth of experience in the industry, moving loads of all kinds all across the country.

USA Truckload Shipping’s extensive network of carrier partners can get your goods where they need to go while offering real-time monitoring and GPS check-ins.

Our trucking services include:

Get a quote today or call us directly at (866) 353-7178 and do the best for your business shipping needs by working with a carrier that won’t let you down.

R+L Global Logistics

315 NE 14th St., Ocala, FL 34470