Dry runs can be a costly and frustrating problem for any business that relies on freight shipping. They can increase your costs and create delays that slow down your supply chain. Understanding why dry runs happen and how to prevent them is key to keeping your shipments on track.

Key takeaways:

Dry runs are a nuisance, but they won’t be the end of your business. We’ll give you a closer look at how they work and the steps you can take to prevent them from happening.

A dry run is what happens when a truck driver is unable to pick up cargo for delivery at the designated time. The truck driver, or carrier who hired them, will charge you full price to make another trip to retrieve the freight as well as a fee for the dry run.

Such events raise costs and create major disruptions for your business operations. Understanding why dry runs happen and how to avoid them can help save money and keep supply chains moving smoothly.

Dry runs are typically caused by factors well beyond your carrier’s control.

The most common reasons include:

We’ll explain these factors in more depth in the following sections.

Drayage refers to short-distance transportation of cargo, usually between ports, rail yards, and distribution centers. Since drayage involves a lot of moving parts—such as coordinating with terminals, securing chassis, and scheduling appointments—dry runs are a common problem.

For example, if a trucker arrives at a port to pick up a container but finds that the container is unavailable, the trip is wasted. In some cases, truckers on their way to retrieve a container might arrive late.

This can be caused by anything from traffic congestion to port delays. Many ports are located in major metropolitan areas, where traffic is high. If a trucker gets stuck while on their way to your container, they might arrive past the pickup time. Port delays are another matter, which we’ll explore next.

Related: What Is Drayage?

Port congestion can cause truck drivers to spend long amounts of time waiting for a container to be ready for pickup. In some cases, they might be unable to retrieve the shipment altogether due to logistical bottlenecks.

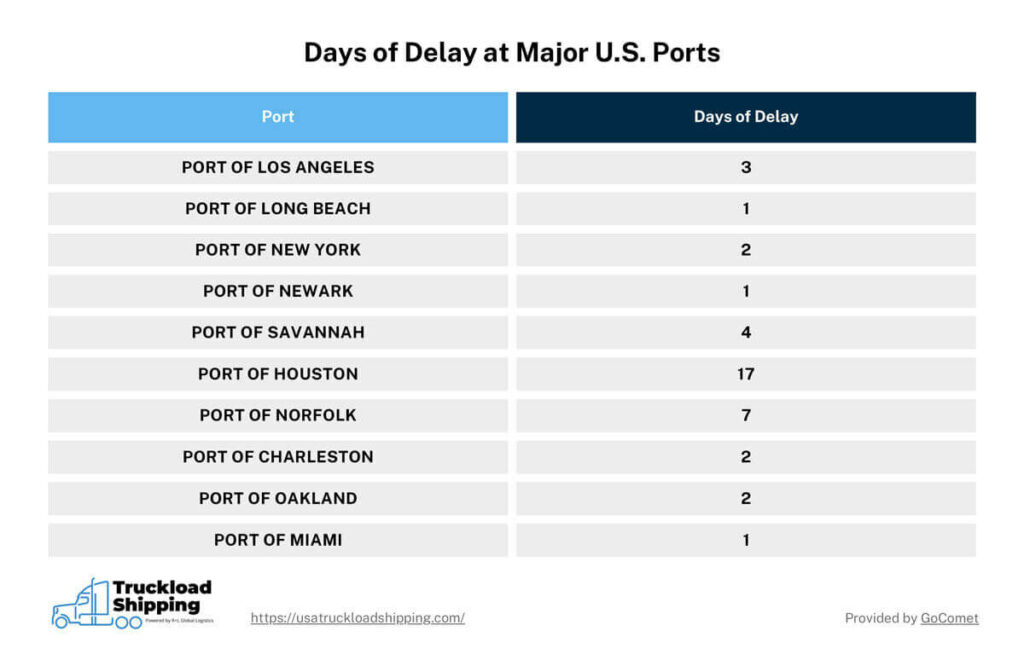

In recent years, there was a surge in port congestion. While this was largely caused by the COVID-19 pandemic and the worst is (hopefully) behind us, repercussions of it are still being felt. Consider a recent data snapshot I’ve provided that shows congestion at some major ports in the United States.

Keep in mind, the days of delay can vary over time, so be sure to always check current wait times, either by contacting the port itself or using trackers available online. The COVID pandemic may be mostly in the past, however, there are many other factors that can contribute to the problem.

Your business likely relies on imported shipments of product before you start shipping domestically. That means you’ll need to stay aware of these challenges and work with logistics providers to plan for potential delays.

Cargo release is the authorization that allows goods to be picked up from a warehouse, distribution center, or customs facility. There are a variety of reasons that cause cargo release issues.

These include:

If your cargo can’t be released, your carrier won’t be able to pick it up. You’ll have to pay them for a second trip to pick up your freight once any issues have been resolved.

Related: Documents Require for Domestic Shipping

Carriers impose a dry run fee on shippers when they can’t pick up or deliver their freight. After a dry run, carriers will have wasted their time, money, and resources. The purpose of the fee is to compensate them for the expenses they spent.

The cost of dry run fees vary depending on the situation, but they typically range from $75 to $100. Some trucking companies may charge more if the driver was held up for an extended period before being turned away.

Yes, dry runs can have a significant negative impact on your shipping operations. Let’s take a closer look at the repercussions you’ll face when they occur.

While these repercussions can seem overwhelming, there are a variety of methods you can implement to prevent dry runs. We’ll discuss these more in the following sections.

One effective way to avoid a dry run is through a pre-pull. A pre-pull occurs when a trucking company picks up a container from a port or rail yard ahead of time and stores it at their facility until final delivery is scheduled. They’re typically performed before the last free day (LFD) at the port.

Pre-pulls help prevent dry runs by ensuring that the container is already available outside the port when the driver is ready. This strategy is especially useful for avoiding congestion at busy ports and ensuring a smoother pickup process.

Not only will a pre pull help prevent dry run fees, it will also help prevent demurrage charges that can occur when containers remain at a port longer than the allotted free time.

Dry runs are guaranteed to happen when shipping freight, but there are many strategies you can implement to reduce the chances it’ll occur.

Some key strategies include:

By taking these steps, businesses can minimize the risk of dry runs and keep freight moving efficiently.

At USA Truckload Shipping, we can get your containers out of any port in the U.S. without the risk of an unnecessary dry run. We have drayage facilities with chassis’ near the country’s major ports that stand ready to pick up your freight. Our company also provides a variety of other services that you can use to move your cargo across the country.

Start your relationship with USA Truckload Shipping by filling out your Request for Proposal (RFP). For any inquiries, reach out to us at (866) 353-7178 or navigate to our contact page.

Our transportation experts are ready to share their expertise by guiding you through the shipping process.

R+L Global Logistics

315 NE 14th St., Ocala, FL 34470