Block and brace practices are key to the shipping process, particularly over-the-road trucking. However, implementing block and brace methods is a challenge. Varying load sizes, shapes, and weights demand different approaches to cargo securement. Failure to properly block and brace cargo can cause goods to be damaged in transit.

Key Takeaways

This article sheds light on the best practices in blocking and bracing to secure cargo on trailers and in shipping containers effectively.

When it comes to securing cargo, there is no one-size-fits-all approach. Multiple techniques exist for both blocking and bracing. Let's examine the individual components that comprise this practice.

Blocking involves the use of various materials to prevent cargo from shifting or moving side-to-side movement during transportation. The main goal is to keep the load from moving horizontally.

Common materials used when blocking a load include:

By preventing lateral movement, blocking reduces the risk of cargo tipping over or shifting, which could compromise the stability of the vehicle and cause damage to the goods in transit.

Bracing, on the other hand, involves stabilizing cargo to prevent vertical movement. It employs supports such as bars, rods, or straps to keep cargo from shifting up and down. The primary objective is to prevent cargo from tipping or becoming unstable due to shifts in weight distribution during transit.

Some of the most common bracing materials are:

Bracing keeps vertical movements in check, minimizing the risk of cargo falling or causing the trailer to tip over. It is a key facet of safe cargo transportation that should never be overlooked.

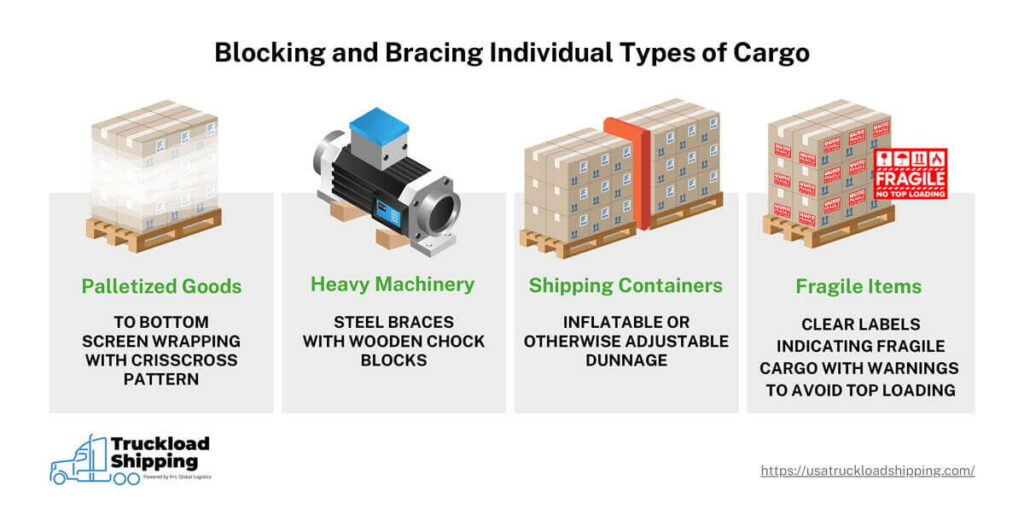

Various types of loads require different approaches to blocking and bracing. Improperly secured cargo can easily lead to costly damage and upset customers.

We’ve laid out some common types of cargo and the best block and brace freight practices for each.

Distributing the weight evenly across the trailer is another important part of blocking and bracing. It ensures that heavy items are placed low and toward the center of the trailer or container, which is vital to preventing tip-overs.

Related: How to Ship Glassware Without Shattering Expectations

Any time you haul large cargo via a trailer, some kind of brace and block technique must be used. The size and shape of cargo dictates which techniques should be used to comply with regulations.

The Federal Motor Carrier Safety Administration (FMCSA) sets standards for cargo securement to ensure some consistency from one cargo company to another.

FMCSA regulations dictate that cargo be secured at regular intervals (5’ to 10’ depending on its weight) with appropriate straps. Since this limits lateral and vertical movement, strapping down a load can be seen as a form of both blocking and bracing.

Depending on the shape of the cargo, it may also require wedges, cradles, and other movement-limiting implements. This rule mostly applies to cargo that is likely to roll in transit, such as pipes or drums.

Transportation via cargo liners and trains are two of the most common methods of intermodal transportation, and the practice of block and brace is key here as well. Containers moving side to side on a cargo vessel or train can damage or destroy cargo.

To block and brace a container properly, keep these three elements in mind.

Using the correct block and brace method is especially important for shipping containers traveling by rail. This is due to a gentle but persistent vibration during transit, which increases the likelihood of cargo shifting.

Proper blocking and bracing of the container prevents damage during drayage, transit to distribution centers, and the final mile.

Related: What is Drayage? A Comprehensive Guide to First Mile Freight

As you can see, block and brace techniques are crucial to ensuring the safety of your cargo. However, you don’t have to go it alone. USA Truckload Shipping is a leading company in the logistics sector, and we’re dedicated to ensuring that your cargo is transported safely and efficiently.

These are just some of the services we offer.

We employ expert techniques and high-quality materials for blocking and bracing to safeguard your goods. If you’re looking for reliable and secure cargo transportation, send us an RFP today, or call our expert team at (866) 353-7178. We’re standing by to handle your shipping needs with the expert knowledge and care you deserve.

R+L Global Logistics

315 NE 14th St., Ocala, FL 34470