Dry van trailers are the backbone of the transportation industry, serving as the primary means of moving a vast array of goods across the country. Understanding the different types of dry van trailers is essential for you to optimize your logistics strategies and ensure the safe and efficient delivery of your products.

The common sizes and types of dry van trailers used in both LTL and FTL shipping include:

Will discuss these trailers and more to give you a better understanding of the options available to you.

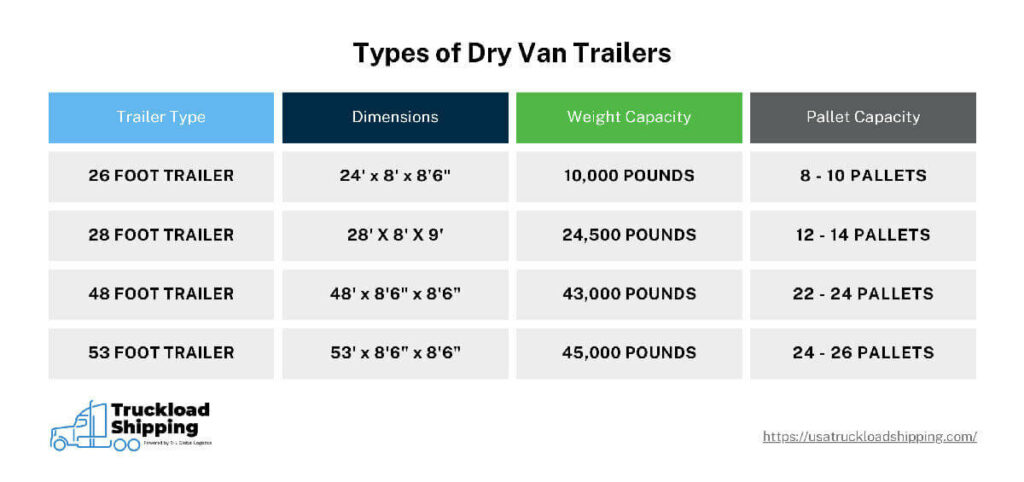

There are many common types of dry van trailers available for truckload shipping. We’ve provided a graphic that shows their dimensions, weight capacity, and the maximum amount of pallets they can hold.

Regardless of the freight you’re moving, how goods need to be transported, or the size of the total load, you can rest easy knowing there’s a trailer right for your load.

Related: Straight Truck vs Tractor Trailer

As outlined above, dry van types differ in their length, dimensions, max load capacity, and pallet capacity. However, they also come in ventilated and non-ventilated forms. Ventilated dry vans are primarily used for transporting plastics, certain perishable food and beverage items, and plants.

This is trailer is perfect for freight that needs fresh air, but doesn’t require outright refrigeration.

Some scenarios call for the use of a dry van trailer, while others do not. To make it easier for you to determine if you should use one, we’ve listed different types of freight that will benefit from this equipment.

In essence, if your cargo needs to stay dry and protected from external conditions, but doesn’t require temperature regulation, a dry van trailer is the appropriate choice.

Dry van trailers are a go-to choice for many shippers, offering flexibility and protection for a wide range of goods. However, like any shipping method, they come with both benefits and limitations. Understanding these factors can help you determine whether a dry van trailer is the best option for your freight.

Let’s start by looking at the advantages:

Now that you know the pros, let’s weigh them against the disadvantages:

Ultimately, you’ll need to carefully weigh the needs of your shipment to determine if you should use a dry van or a specialized trailer for your freight.

Not all types of freight should be shipped in a dry van trailer. Fortunately, there are a variety of other trailers that might be better suited to your shipments.

This includes:

Let’s take a closer look at these trailers and the best times they should be used.

Refrigerated trailers, commonly known as reefers, are equipped with temperature control systems. This makes them ideal for transporting perishable goods that are temperature-sensitive.

Shipping with reefer trailers is more expensive than dry vans. This is due to the operational costs that come with using refrigeration units attached to them and the maintenance that keeps them working.

Intermodal trailers are designed for seamless transportation of containers. They’re typically used to move containers out of an ocean port to a nearby warehouse for unloading. This service is often referred to as drayage. However, intermodal trailers can be used when you need to ship containers over long distances.

Conestoga trailers are flatbed trailers fitted with a rolling tarp system, which provide the flexibility of a flatbed with the protection of an enclosed trailer. They are suitable for transporting oversized or oddly shaped cargo that requires protection from the elements but cannot be loaded into standard dry van trailers.

Items commonly transported using conestogas include:

The mechanical components of conestoga trailers will need maintenance, but not to the point that operations costs to use them will increase exponentially.

Flatbed trailers are open platforms without sides or roofs. The open design allows for loading at any side. They’re perfect when you need to ship bulky cargo that won’t be ruined by exposure to the elements.

They come in a variety of configurations:

Many flatbeds, like double drop decks and lowboys are designed with tall freight in mind. They can transport cargo while staying within allotted height requirements. The hitch on removable goosenecks can be taken off, which allows the trailer to be used as a makeshift ramp that vehicles can be driven on.

Selecting the appropriate dry van trailer is crucial for ensuring the safe and efficient transportation of your goods. At USA Truckload Shipping, we are committed to providing tailored solutions that meet your unique shipping requirements. Our comprehensive services include:

We invite you to experience the exceptional service and dedication that USA Truckload Shipping offers. Start your relationship with us by filling out your Request for Proposal (RFP). Call us at (866) 353-7178 or navigate to our contact page if you have any questions about the services we have to offer.

R+L Global Logistics

315 NE 14th St., Ocala, FL 34470