Those new to planning an ecommerce shipping budget need to become familiar with the density-based rate system preferred by LTL companies. Every item, from feather-light foam panels to heavy machinery parts, presents its own unique challenge. Knowing how these freight density rules affect your costs could make or break your shipping strategy.

Key Takeaways:

We are going to take a comprehensive look at freight density and everything that’s involved in it for LTL shipping.

Freight density refers to the amount of space that an item may occupy in relation to its weight.

This measurement is then used by certain shipping companies, mainly in the less than truckload (LTL) industry, to determine how much it would cost to ship your products. Official freight classification systems are established by the National Motor Freight Traffic Association (NMFTA). Knowing how to calculate your freight's density early on can help you budget accordingly.

If the freight density you report to the carrier is incorrect, you may face additional charges when the freight is reweighed and measured at the terminal.

The first thing I’ll do is show you how to calculate the correct density of a shipment. Afterwards, we’ll examine a few ways that this ends up impacting shipping and logistics.

The first step to calculating density is to measure weight and volume.

If your shipment is in multiple boxes or pallets, each one can be measured individually. However, you’ll need to figure out the combined measurements to get an accurate rate.

For packages that are awkwardly sized, base the measurement on the furthest points along each axis. That is to say, height, length, and depth again. Basically, you’re placing the item in a figurative box, and then measuring that.

Once you have taken the measurements to find weight and volume, it’s time to calculate the density. Divide the weight of the shipment by the total volume. The result is measured in pounds per cubic foot.

The formula for density is:

It is critical that you keep the same measurement standards throughout the process. All measurements MUST follow the U.S. standardized system. If you forget to convert something from kilos or centimeters into pounds and inches, your results will not be accurate.

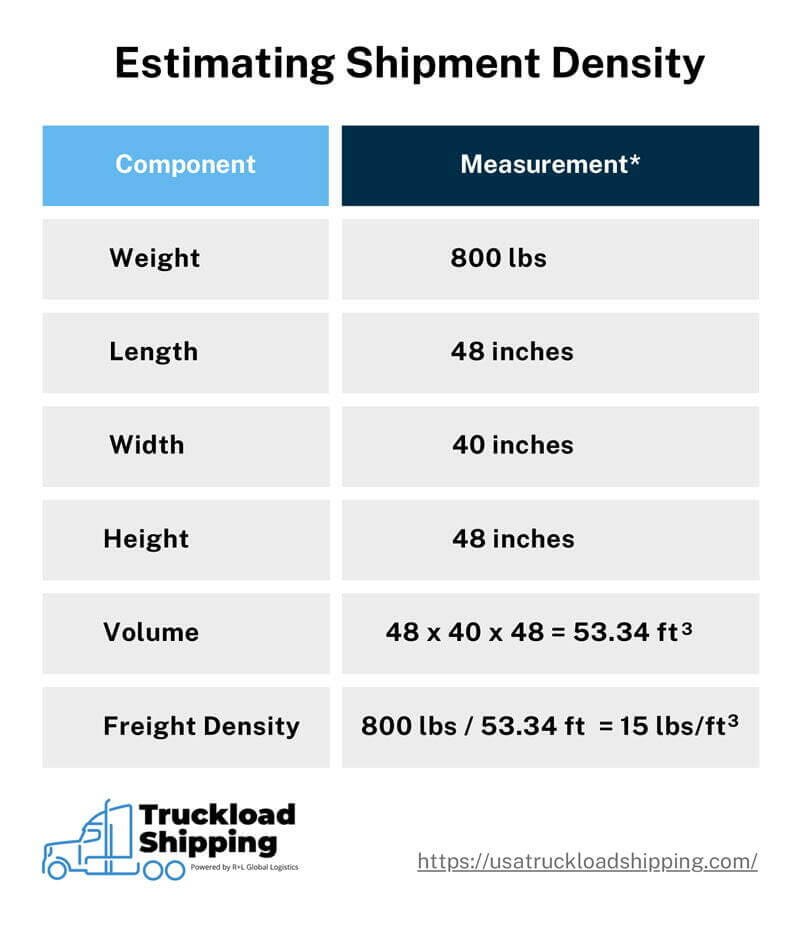

To illustrate, let’s calculate a shipment of flat pack furniture, a medium-heavy but compact shipment.

A single pallet would come in at 800 pounds, taking up 53.34 ft³. The overall density would be 15 lbs/ft³, placing it about midway down the NMFTA’s LTL freight class system. Chances are, it can be easily stacked, which means even three or four pallets can be shipped for a good price.

Related: LTL Freight Class vs NMFC

Density directly impacts your freight rates because of the role it plays in the calculation of freight class, a standardized classification system used in the freight industry.

It’s important to note two main things:

While it may seem simple enough, the decision of whether shipments should be charged by weight or density tends to operate on a scale. Let’s go into this in more detail.

A small, compact item, even one of considerable weight, is often easier to stack and handle. It leads to a more efficient use of space, which allows the carrier to pack more into the trailer. The overall effect is the lowering of costs per package.

On the flip side, lower density goods take up more space relative to their weight, which leads to higher freight costs. These items may be more fragile or just an awkward shape that doesn’t disperse weight well. This may prevent other items from being stacked on or near it, limiting what the carrier can ship.

The loss of efficiency is going to cost a shipper space (as in potential profit) that could have been used for other packages, even if it’s lighter and technically not as much of a burden.

Consider the following scenario to understand why.

Think of the average dry van trailer, which can accommodate about 4,000 cubic feet of cargo. You have two customers, each wishing to ship cargo that takes up the same amount of cubic space but different densities.

On the one hand, they can charge more to Customer A because they're using more of the truck's weight capacity, which affects fuel consumption. However, that can be offset by being able to use the rest of the space for other customers, meaning Customer A is still likely to get a good rate.

The low-density cargo isn’t adding much weight, but does take up valuable space. By not being able to use that space for another client, the carrier makes less profit overall. This translates into higher shipping costs for Customer B to make up the difference, which means they will likely pay a higher rate than Customer A.

Charging by density allows the carrier a means to balance out the difference between the weight and space.

This has led to freight classes. These are categories defined by the National Motor Freight Traffic Association (NMFTA) that consider density, among other factors, when standardizing freight pricing across the industry. More on this in the next section.

However, when a shipment takes up more space per density, a density deficit is often triggered, leading to additional surcharges. These would be set by individual carriers rather than the NMFTA.

For more on estimating your freight costs, check out: How to Calculate Freight Shipping Costs.

As mentioned, shipments that are charged according to their density (LTL shipments) are given a specific freight class by the NMFTA.

This classification system makes it possible for carriers to set pricing that accurately reflects the cost of transporting a shipment. Since its use is widely accepted, it also eliminates confusion among clients. Everyone is on the same page regarding the nature and cost of a shipment, so prices remain competitive and predictable.

To keep track, there is a freight class density chart.

The Freight Class Density Chart is a tool used to determine the freight class of a shipment based on its density. This chart is part of the National Motor Freight Classification (NMFC) guide established by the NMFTA.

The chart lists different ranges of freight density, each associated with a specific freight class. By calculating the density of their freight, shippers can estimate which freight class they are likely to be assigned. This is useful for:

There are 18 different classes in total, and they range from 50, which is the cheapest and most dense, to 500, which is the most expensive and least dense.

The NMFTA maintains a simplified list and makes it available to carriers and shippers alike. Even when you are able to accurately measure your shipment’s density, realize there are other factors involved which may alter which freight class your carrier assigns to a load.

Working with a trusted carrier is the best way to ensure your shipments are classed correctly. Reputable carriers will always use the NMFC’s updated requirements for classifying your shipments according to specific codes known as NMFC numbers.

NMFC numbers (or codes) were created when transportation regulators came to realize that there was a need for more specific standardization. Considering the almost impossibly wide variety of products that ship via LTL, freight classes alone just aren’t enough.

This system relies on the existing Freight Class system, but goes above and beyond by assigning a specific code to all types of products.

NMFC number determination is based on four factors, including density. The other three are:

The extent to which each of these affects the final cost isn’t definite. As products evolve, their codes get ranked higher or lower on the freight class chart.

For the most consistent service and pricing options, keep up a good relationship with your preferred carrier. They may not be able to lock in prices all the time. However, open lines of communication go a long way towards making sure that you aren’t blindsided by changes, either.

Related: How Do I Find My NMFC Code: Classifying With Confidence

The majority of LTL carriers are using density-based pricing systems within the freight industry. Much of this is due to how it promotes efficiency during the packaging process.

Before the introduction of classifications and freight density, many businesses would simply package their shipment in the most convenient box for them, regardless of the size, quantity, or weight of the items within. Carriers and manufacturing businesses alike have come to see how wasteful this can be.

By requesting density-based quotes, everyone in the industry benefits from the greater efficiency involved.

Density-based pricing has already become incredibly popular throughout the industry and has been adopted by companies using air, land, and sea.

If you know that your shipments may end up traveling internationally, requesting quotes based on density will save you time and money down the line.

Related: How to Reduce Freight Costs: Save Money on Land, Sea, and Air

Although NMFC numbers assigned to freight class rankings are unique to the United States, density-based rates are not. LTL carriers in Canada, a likely trade partner in cross border shipping, also use a density based system for freight rate calculations.

Whatever your shipment may be and whatever size, classification, or density, you should always be mindful of the shipping company you use. If you aren’t sure exactly which services you need to look into, USA Truckload offers freight and logistics consulting to help.

USA Truckload Shipping provides a trusted service that can cater to every shipping need.

We have the skills and expertise to move your loads at competitive prices. Get your shipping back on track with our experienced carrier partners.

Call us at (866) 353-7178 or get a freight quote online today. Ready to lock in some prices? We also accept RFP proposals right through our site.

R+L Global Logistics

315 NE 14th St., Ocala, FL 34470