Trailers and cargo containers can be filled with all kinds of freight. When it comes to loading freight, shippers typically stick to two primary methods: floor loading and palletizing. You’ll need to have a thorough understanding of each before deciding which one to use.

Key takeaways:

In our article below, we’ll provide more details about floor-loaded freight and palletized shipping.

Freight that’s loaded directly onto the floor of a trailer and stacked toward the ceiling is called floor-loaded freight. It may also be referred to as non-palletized. Since there’s nothing to secure it in place, this type of cargo is considered “loose”.

Most floor-loaded shipments are full of packages that are too small to be secured by pallets. However, some floor load products are extremely large and awkwardly shaped.

These can include products like:

While oddly shaped items are often floor-loaded, regular packages can also be non-palletized.

Floor loading isn’t as simple as piling boxes upon one another. Instead, cargo is stacked to form a wall. Many transportation companies have specific rules they require their warehouse workers to follow when they handle floor-loaded freight.

These guidelines are meant to protect workers and packages during the loading and shipping process.

Floor-loaded freight that’s secured correctly will stay in place, which makes it less likely for cargo to sustain damage.

There are many pros and cons to using floor loading freight that you should consider.

Pros:

Cons:

Despite the benefits offered by floor-loaded freight, it’s a far more risky way of transporting freight.

Palletizing is when cargo is secured to a pallet, typically with stretch wrap. These platforms are either made from wood or plastic. They’re best suited for carrying boxes.

Just as with floor-loaded freight, palletized freight has its own unique style of loading that roughly all shipping companies use.

Here are the steps to load a pallet into a container or trailer:

These guidelines ensure that pallets and the freight they carry remain secure.

Shipping freight on pallets is much more common than floor-loaded shipping. That said, palletizing has its unique advantages and disadvantages as well.

This includes:

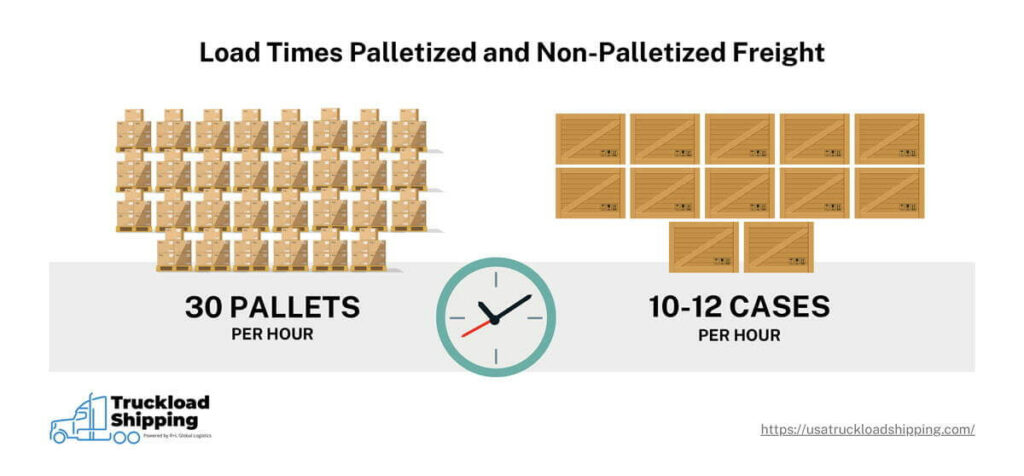

Additionally, every time a pallet is moved, multiple packages move along with it. This is much more efficient than loading and unloading one package at a time. To prove this, consider some data comparing pallet and non-palletized loading times.

The main downside of using pallets is they don’t fill a cargo container or trailer as efficiently as floor-loaded freight. Despite being able to stack and secure multiple packages to its base, there will still be unused space in the container that transports them.

This means that you will be paying for empty space when you ship palletized freight. You will also be paying extra costs for the use of pallets.

There are trade-offs to both floor-loaded freight and palletized freight. The one that works best depends on how much time you have to ship and how much you're willing to spend on your shipments.

If you’re shipping awkwardly shaped cargo that doesn’t fit well on a pallet, then it’s best to use floor loaded freight. Labor costs will be higher, but other shipping expenses will be dramatically lower.

Palletizing is the better option for conventionally shaped cargo that fits perfectly inside a box. This will be particularly useful if you’re shipping fragile freight, as a pallet will give your products better protection.

Related: Shipping Skid vs Pallet

Amazon FBA, or fulfillment by Amazon, is very particular about how freight arrives at their warehouses. They prefer that freight arrives at their warehouse palletized.

While they will accept floor-loaded trailers, they have many rules as to how they should be stacked. Not adhering to their guidelines for floor loaded or palletized shipments could result in your shipment being refused.

If you have palletized freight to ship, then USA Truckload can move it. We’ll pair you up with the perfect carrier from our vast network to pick up your cargo and transport it to the final destination. You can count on our decades of logistics experience to make all your shipments a success.

We can also offer a variety of other services when you choose us as your 3PL.

Start a relationship with USA Truckload today by filling out your Request for Proposal (RFP). For any questions you might have, call our team at (866) 353-7178.

R+L Global Logistics

315 NE 14th St., Ocala, FL 34470

Can a container shipment be floor loaded at port of departure…then palletized at port of entry to load on to straight trucks or trailers?.. is this a common procedure?

Our ship for a floor loaded container… 20 feet long… would be 256 boxes… each box approximately 19 inches wide, 19 inches high, 3 different widths:17,25.5,28.5 inches wide.. total weight 5,376 pounds