The ability to move shipping containers in and out of port is a critical part of many business supply chains. Container chassis make this possible, so having a solid grasp of the fees involved is necessary. Multiple factors and situations can influence the rise and fall of chassis charges.

Key Takeaways:

The following information will give you a breakdown of chassis fees, related charges, and the varied types of chassis available.

A chassis is a uniquely designed trailer that carries marine shipping containers to and from an ocean port to other destinations. A chassis charge applies when your cargo gets transported to either drayage or a warehouse from an ocean port.

The chassis charge is a flat rate applied by port rentals, drayage pool rentals, or a carrier/3PL. Drayage services are the most common solution for chassis shipping from the ports.

Before 2009 ocean carriers actually provided chassis at the ports. Unfortunately, this is no longer the case, which is why drayage and 3PLs now charge for the service.

Various charges are applied when utilizing a container chassis, from daily rental fees to fuel surcharges. It is important to note what these charges are and whether they are avoidable or negotiable.

Secondly, realize that chassis fees tend to go hand in glove with port drayage services (what chassis are most used for). Drayage fees are their own service charge, and while chassis fees may get bundled with them, the charges I’m describing here are specific to trailer uses.

Related: How to Calculate Drayage Rates

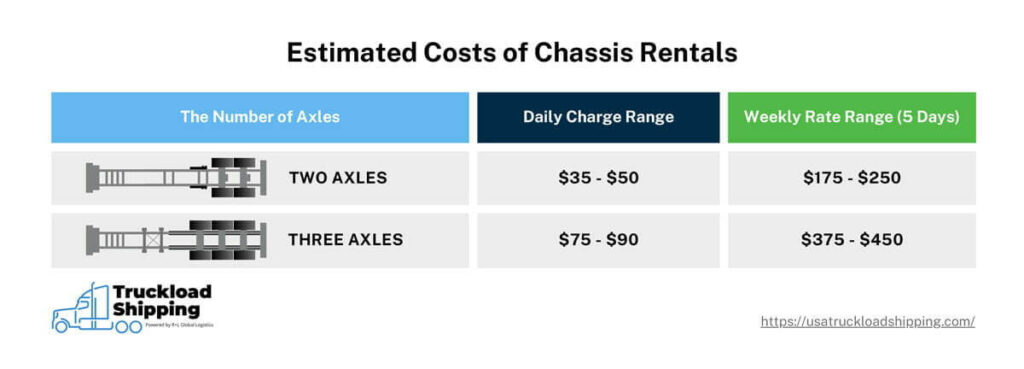

At the start is the base chassis charge for daily or weekly (more common) use. You can rent/contract various chassis types, but the greatest determiner of this cost will be the number of axles. Use the provided guide to help with estimates.

Where in the range your rate lies can depend on various factors. Busier ports with greater chassis demands, such as Los Angeles or Newark, are likely going to be on the higher end of the scale.

Other factors, such as peak season demands, can also inflate prices. Providers have the right to set their own rates. However, you may find that those who own their assets rather than contract out to carriers can give you a better price, at least for the usage fee.

In any case, rentals from a chassis pool, rail terminal, or 3PL can take up to a week to secure, so be sure to plan ahead.

As mentioned, a tri-axle trailer, one with three axles on the chassis, will incur higher rates. More axles increase the load-bearing weight a chassis can transport, which may be necessary to meet Department of Transportation (DOT) weight requirements.

If the weight of your load is more significant than expected (or you reported the wrong weight), and a two axle chassis isn’t sufficient, your provider will increase the rate to get a tri-axle. Not only will you end up paying more, but you’re likely to delay getting your shipment picked up, thus risking additional fees from the port.

If you want to avoid this charge, you’ll have to ensure the weight of the containers you need shipped fall within the range of a two-axle chassis.

A chassis split happens when the shipping container is in a different location than the chassis. The charge is the cost for the driver to haul the empty chassis to where the container is.

When providers use a rented chassis (not their own assets), a predetermined chassis pool will dictate and manage the pickup and termination point for all chassis rented. This has become an increasingly standard practice to manage availability.

A chassis split charge in supply chain logistics is almost standard because of this, so expect to see it on your quote/invoice. The average fee can range from $50 to $150 depending on how far the driver may need to travel.

After a container has been delivered and emptied, this fee may also apply. In this case, it may be referred to as a reposition charge, aka chassis repo charge, and is the direct cost for moving the empty cargo container and chassis to the closest hub.

This charge occurs when a shipper cannot accept the delivery before the last available free day granted by the port, but still wants the carrier to pick up the container. This is often done to avoid being charged port demurrage fees.

By paying the pre-pull charge, the carrier will remove the container from port and generally keep it in a storage yard until you can receive the delivery.

There are a few scenarios where this might happen:

The charge per container ranges between $120 to $300. Even on the high end, these fees are meant to be less than what ports would charge in demurrage/additional storage fees. On average, estimate them at one third of what the port fees would be.

Related: Detention Fees: Tips to Avoid Unnecessary Charges

Now that we’ve reviewed what the various charges are, it’s easier to estimate what you’ll pay for chassis during a drayage haul

Once you know your drayage rate (typically a cost per mile), you can start adding in other expected fees as discussed here. You can use the ranges I’ve provided, but realize that the fees won’t be final until the full service has been provided. There is no absolute set number for chassis fees or any associated charge.

Clear communication with your service provider, whether you’re using a chassis pool or contracting with a 3PL, is the best way to be aware of your final charges.

Despite your best efforts, there are factors outside your control that impact supply chain costs, including chassis charges.

These events might be inevitable, but that doesn’t mean you can’t do anything about them. Having emergency plans in place for unexpected events (and expenses) can help your business more easily overcome such situations.

Related: What is a Fuel Surcharge and How is it Calculated?

When looking to reduce charges related to chassis, awareness of potential savings is essential. There are three strategies to consider when trying to minimize chassis fees.

These will apply in most if not all cases, so it is critical to familiarize yourself with them.

For businesses looking to schedule routine pickups, working with 3PLs that offer freight brokerage on a contract basis is the easiest way to fulfill cost reduction goals. Spot rates will always be more expensive and, while sometimes needed, should not be part of your long-term business plan.

Chassis charges are now an inevitable part of contracting drayage services, so you should be aware of how and why you are charged certain fees. As always, you also want to make sure that you are getting quality services that you can rely on.

That’s why USA Truckload Shipping is ready to provide you with best-in-class shipping solutions. Our friendly experts can get you set up with a quality chassis on time for all your incoming port shipments on a schedule that works for you.

No matter the freight, we have a service for you:

Call us at (866) 353-7178, or send us your quote request directly through our online form.

R+L Global Logistics

315 NE 14th St., Ocala, FL 34470

I would like to receive quote